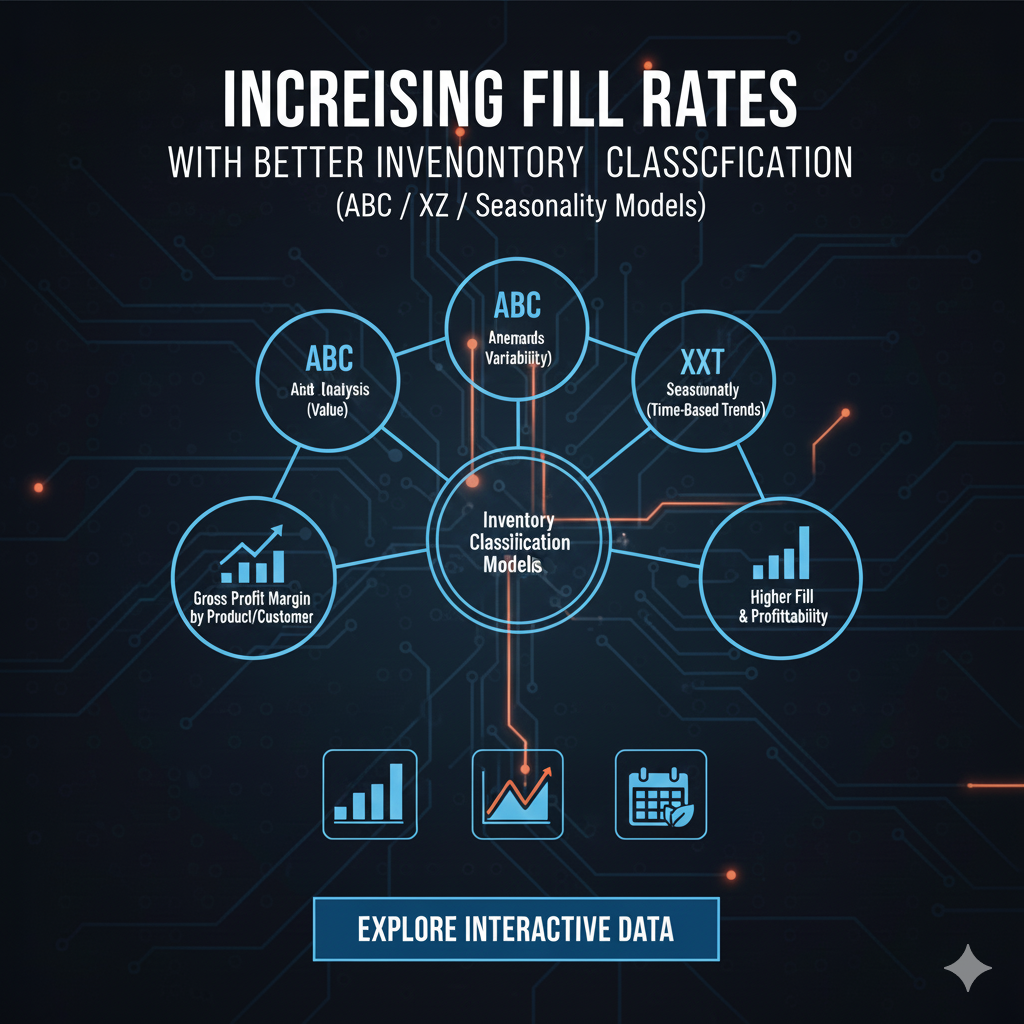

Increasing Fill Rates with Better Inventory Classification (ABC / XYZ / Seasonality Models)

How smarter segmentation turns inventory data into higher service levels, lower stockouts, and healthier margins.

Introduction

In today’s supply chains, fill rate is one of the clearest indicators of operational excellence. Whether you are a building materials distributor, manufacturer, or wholesaler, customers expect products to be available when they need them. Missed fill rates don’t just result in lost sales they erode trust, push customers to competitors, and inflate operational costs through expediting and firefighting.

Yet many organisations still manage inventory using one-size-fits-all rules. The reality is that not all SKUs behave the same. Some drive most of the revenue, some are highly predictable, while others are seasonal or erratic. Treating them equally is one of the fastest ways to create stockouts and excess inventory at the same time.

This is where inventory classification models - ABC, XYZ, and Seasonality analysis - become powerful levers for increasing fill rates without simply carrying more stock.

Why Fill Rates Suffer Despite “Enough” Inventory

Many companies assume that low fill rates mean insufficient inventory. In practice, the problem is usually misallocated inventory.

Common causes include:

High-value SKUs being understocked

Slow-moving items consuming working capital

Volatile-demand items forecasted like stable products

Seasonal spikes treated as anomalies rather than patterns

Better classification allows businesses to prioritise the right inventory decisions for the right SKUs, directly improving service levels.

ABC Classification: Focus Where It Matters Most

ABC analysis segments inventory based on business impact, typically revenue or margin contribution.

A-items: ~10–20% of SKUs generating ~70–80% of revenue

B-items: Moderate importance, stable contributors

C-items: High SKU count, low revenue impact

How ABC Improves Fill Rates

By identifying A-items, organisations can:

Apply tighter safety stock policies

Review forecasts more frequently

Prioritize replenishment and supplier reliability

Instead of spreading attention evenly, teams focus effort where stock outs hurt the most.

XYZ Classification: Managing Demand Variability

While ABC looks at importance, XYZ classification focuses on predictability.

X-items: Stable, predictable demand

Y-items: Moderate variability or trend-based demand

Z-items: Highly volatile or sporadic demand

Why Variability Impacts Fill Rates

Applying the same forecast model to X and Z items is a common mistake. Z-items often cause:

Chronic stockouts

Excess safety stock that still fails

Poor forecast accuracy metrics

By classifying demand behavior, businesses can:

Use statistical forecasting for X-items

Apply trend and causal models for Y-items

Shift Z-items to make-to-order, MOQ-based, or service-level driven strategies

This alignment significantly reduces surprise stockouts.

Seasonality Models: Planning for What You Already Know Is Coming

Seasonality is often visible in hindsight but ignored in planning.

Examples include:

Construction materials peaking in warmer months

Retail products tied to holidays

Project-based demand cycles

Turning Seasonality into Higher Fill Rates

Seasonality-aware classification enables:

Pre-build strategies before demand spikes

Dynamic safety stock adjustments

Supplier alignment ahead of peak periods

Instead of reacting to demand surges, organisations anticipate and prepare, preserving fill rates even during high-volume periods.

Combining ABC + XYZ + Seasonality: The Real Advantage

Individually, each model adds value. Combined, they create a multi-dimensional inventory strategy.

For example:

AX Seasonal: Mission-critical SKUs requiring proactive pre-builds

CZ Non-seasonal: Candidates for rationalisation or on-demand sourcing

BY Seasonal: Moderate importance but timing-sensitive items

This layered approach allows companies to:

Allocate capital more effectively

Improve fill rates without bloating inventory

Align operations, procurement, and sales around shared priorities

Technology and Data: Making Classification Actionable

Manual ABC or XYZ analysis done once a year quickly becomes outdated. Modern operations require:

Automated SKU classification

Continuous demand pattern monitoring

Integration with ERP and planning systems

At Intuitico, we help organisations move from static spreadsheets to dynamic, data-driven inventory classification, ensuring that fill rate improvements are sustained not temporary.

Key Takeaways

Low fill rates are often a classification problem, not a stock problem

ABC focuses effort on revenue-critical SKUs n- XYZ aligns planning with demand variability

Seasonality models prevent predictable stock outs

Combined classification drives higher service levels with lower working capital

Ready to Improve Your Fill Rates?

If your organisation is struggling with stock outs, excess inventory, or inconsistent service levels, better inventory classification is a proven starting point.

Visit our website: https://www.intuitico.io

Email us at “will.chen@intuitico.io“ to learn how data-driven inventory strategies can unlock higher fill rates and stronger margins.

For a free 30 minutes consultation, you can book a meeting using this link:

”https://calendly.com/will-chen-intuitico/30min”